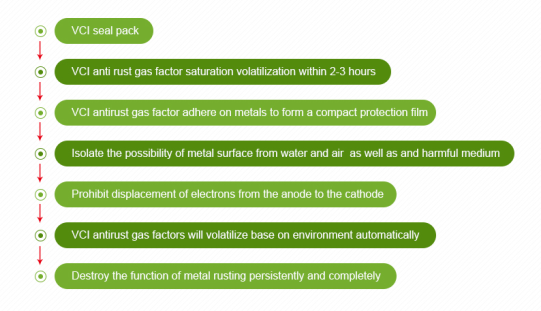

The vapor phase corrosion inhibitor is made from a colorless, tasteless, non-toxic, non reactive, non flammable and non flammable proprietary chemical preparation. These chemical agents release a corrosion inhibitor, A protective film formed on the surface of a metal surface of a metal in a sealed space, isolate the atmospheric corrosion factor from surface of metal. And the electricity from anode flow to cathode. So as to inhibit the occurrence of corrosion reaction.

Once take the metals out from package. The film of vci phase will lost its stable condition on surface of metal. Also its will keep diffusing from metal surface (About in one hour). And clean, dry and corrosion free metal articles will be left.

VCI anti rust factor will be volatilize in the form of gaseous. Can reach to crack, blind hole, groove so on which traditional way of coating can not get, to form protective film.

In order to get expect antirust effect. The VCI anti rust factor in the packaging unit should be avoided of continuous convective exchange with the outside air. If required, it must be strictly controlled the exchange times and the time.

According to customer requirement, also can be combined with a variety of physical barrier methods to optimize the anti rust function, These methods are based on the use of ordinary low density polyethylene, can be achieved via high strength, high tear strength, high resistance to sunlight or ultraviolet, anti-static, low moisture or acid gas permeability of the composite material

VCI is the English abbreviation of Volatile Corrosion Inhibitor, which is prepared by special compounding technology and mixing. It can separately or when being cohesive to proper carrier, directly gasify at ambient temperature and under normal air pressure. This inhibitor can fill the mixed gas containing VCI antirust factors in any interstitial space of the operating unit by its adjustable continuous volatility in a sealed environment. The mixed gas will adhere to the metal surface when it touches the surface to form a compact protection film with thickness of one or more molecule.

The protection film can effectively isolate the metal surface from moisture, oxygen and other harmful atmosphere corrosive factors and inhibit the occurrence of electrochemical reactions resulting in metal corrosion so as to achieve the best antirust and anti-corrosion effects.

There are many different ways to prohibit corrosion. Such as dry atmosphere, Inert gas filled, vacuum, coating oil, or packed by vci package within corrosion inhibitor.

Metal corrosion refers to the process of conversion from metal to metal compounds, also the original mineral form, under the influence of the surrounding environment medium. Under normal circumstances, the more energy the refinery of certain metal consumes, the faster the metal will be corroded.On the surface of metal that has not be treated, there exists little electron ion, which will form the movement from the high-energy area(anode)to the low-energy(cathode) due to the atmosphere corrosion factors to form current. The current will convert the simple substances of metal into thecorresponding stable compounds, thereby generating corrosion.

Copyright © Suzhou Rustop Protcetive Packaging Co., Ltd. All Rights Reserved |Sitemap

Technical Support: